Application problems and material selection of high temperature control valve for steam

What is a control valve?

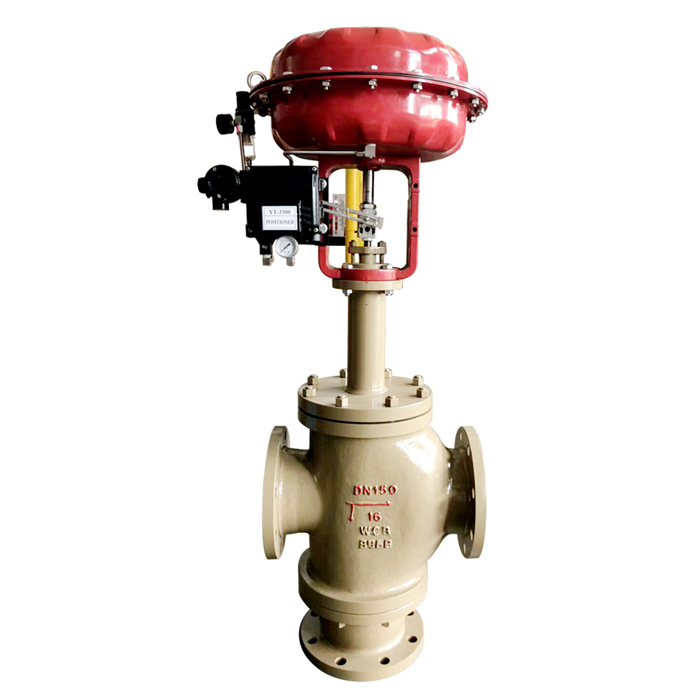

High temperature control valve refers to a control valve with an operating temperature higher than 450 ° C. It can be divided into 450 ~ 600 ℃, 600 ~ 700 ℃ and 750 ℃ .

What are the main problem usually involved with high temperature regulating valves?

Severe thermal expansion and contraction problems reduce the guide gap and the valve regulating member's rotation gap due to expansion, which can cause it to become stuck. Moreover, at high temperatures, the creep caused by the material causes the mechanical properties to decrease.

From the perspective of thermal strength, how to choose the material of the valve body and trim?

For control valve used in the application above 450 ℃, the influence of temperature and pressure on the mechanical strength of the material must be considered in the design and selection. For example, for those valves used in boiler water-feed system and overheat bypass system, general material for valve body and trim is not applicable. Therefore, more durable materials must be selected. The maximum temperature that can be used for general materials is up to 500 ° C. For occasions above 538 ° C, the valve body is usually made of chrome-molybdenum steel. For the highest temperature of about 1035 ℃, SUS310S stainless steel is usually used, and the carbon content of the material must be controlled between 0.04% and 0.08%. For higher temperatures, it is recommended to use a non-metal heat-resistant material lined (can be used at high temperatures of 1200 ° C) or special high temperature resistant and high strength alloys (such as high temperature resistant high strength alloys for engine combustion chambers, which can be directly used for 1000 ℃ high temperature occasions.)

Considering thermal expansion and contraction, how can valve structural measures be taken to prevent leakage?

Leakage can be prevented by the valve seat welding method. When the temperature is as high as 750, the valve seat of the thread connection causes leakage at the sealing surface and the thread connected to the valve body, which can erode the thread and cause the risk of the valve seat falling. In the face of this summary failure, sealing welding of the valve seat should be considered to prevent loosening and falling off

If you have some related question, freely contact us via sales@jhflow.com