Direction and position of cast steel valves installation

Cast steel valves are vastly installed in industrial sectors. It is important to consider the direction and position of cast steel valves.

Direction of valve installation

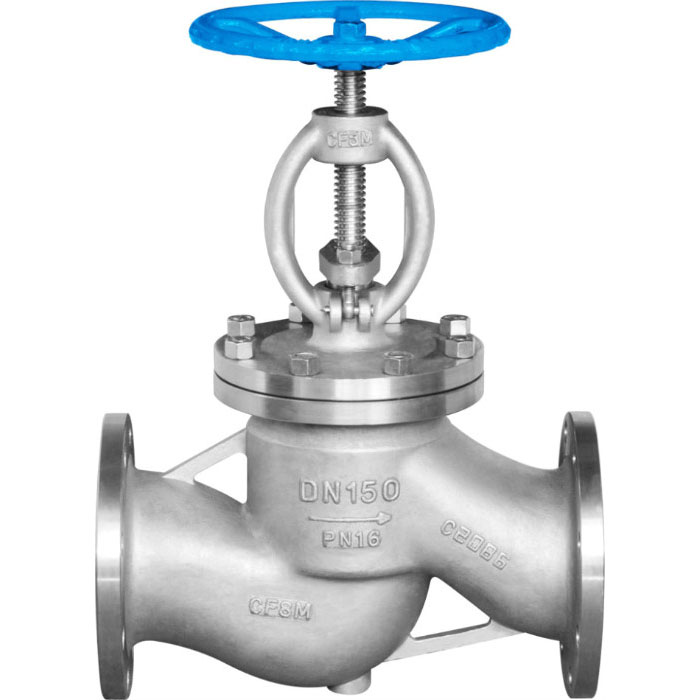

Many valves have directionality, such as globe valves, throttle valves, pressure reducing valves, check valves, etc. If installed reversed, it will affect the effect and life (such as throttle), or stay useless (such as Pressure reducing valve), even causing danger (such as check valves). Generally, the valve has a direction mark on the valve body; if it is not, it should be correctly identified according to the working principle of the valve. For example, the valve chamber of the globe valve is asymmetrical to the left and right, and the fluid should be passed from bottom to top through the valve port, so that the fluid resistance is small (determined by the shape) and the operation can be labor-saving (because the medium pressure is upward). This is why the globe valve can't be reversed. Other valves also have their own characteristics.

Position of valve installation

The valve installation position must be convenient for operation. Even if the installation is temporarily difficult, it is necessary for the operator's long-term work.

1. It is best to have the valve handwheel flush with the chest of the operator (usually 1.2 meters away from the operating floor), so that the opening and closing of the valve is more labor-saving.

2. The hand wheel of the direct buried valve should be facing up and not tilt, so as to avoid awkward operation.

3. The valve against the wall machine should also leave room for the operator to stand.

4. It is necessary to avoid looking up at the sky during the operation, especially acid and alkali, toxic media, etc., otherwise it is very unsafe.

5. Do not install the gate valves with the handwheel facing downwards, otherwise the medium will remain in the bonnet space for a long time, which will easily corrode the valve stem and is contraindicated for certain process requirements. Meanwhile it is inconvenient to replace the packing at the same time.

6. Don’t install OS&Y gate valves under the ground, otherwise the exposed valve stem will be corroded due to moisture.

7. The valve flap of Lifting check valve and hinge pin of swing-type check valve should be vertical to ensure the flexible operation.

8. The pressure relief valve should be installed upright on a horizontal pipe. Don’t get it tilted in all directions.

If you are interested in more information. Let us know freely via sales@jhflow.com