Ball Valves VS Plug valves, what are features and difference ?

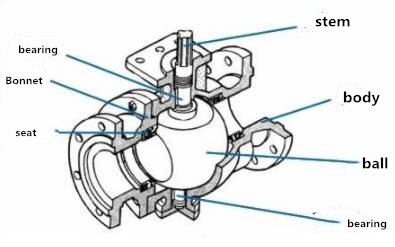

Ball valves and plug valves are two commonly used valve types. Ball valves evolved from plug valves. In principle, ball valves can also be regarded as special plug valves. The plug valve closure member is cylindrical or cone-shaped cylindrical, while the valve closure member of the ball valve is spherical. Both of these valves rely on the close contact between the valve closure member and the sealing surface to maintain the valve tightness, and both rely on the rotation of the valve closure member to open the flow path. Let us take an analysis of their features and difference of both valves.

I. Ball valves

Ball valves are widely used in petroleum refining, long-distance pipelines, chemicals, papermaking, pharmaceuticals, water conservancy, electric power, municipal construction, steel and other industries.

Taking the ball valve manufactured by JHF Valves as an example, the advantages of the ball valve are:

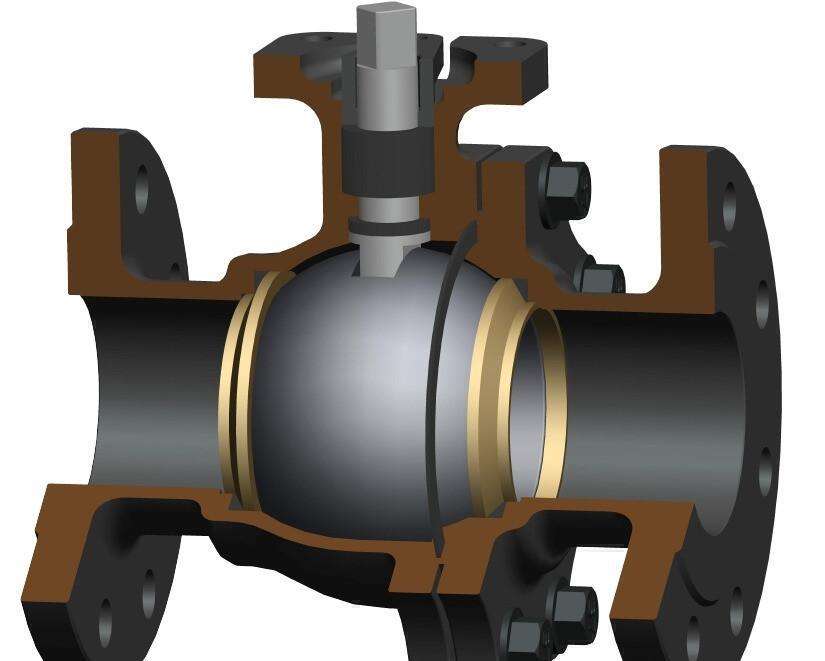

1. The ball valve has low fluid resistance, and the full-bore ball valve basically has no flow resistance.

2. Simple structure, small size and light weight.

3. Reliable tightness. It has two sealing surfaces, which has good sealing performance and can achieve complete sealing. Various resilient and metal material are widely used as the sealing surface materials of the ball valve, increasing the application range.

4. It is easy to open and close quickly. It only needs to rotate 90° from fully open to fully closed, which is convenient for remote control.

5. Convenient maintenance. With simple structure and renewable seat rings, it is convenient to disassemble and replace.

6. When fully open or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium, and the medium will not cause erosion of the valve sealing surface when the medium passes.

7. The ball valve has a wide range of applications, with a diameter ranging from a few millimeters to a few meters, and can be applied from high vacuum to high pressure.

8. Since the ball valve has wiping properties during opening and closing, it can be used in media with suspended solid particles.

II. Plug valves:

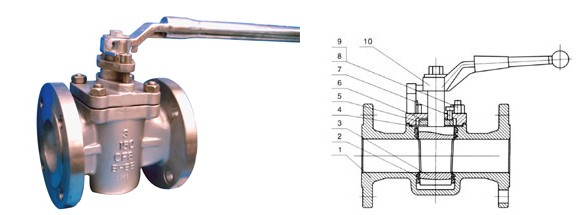

Plug valves are widely used in oilfield exploitation, transportation and refining equipment, and also widely used in petrochemical, chemical, gas, natural gas, liquefied petroleum gas, HVAC industry and general industry.

Taking the plug valve manufactured by JHF Valve as an example, the main advantages of the plug valve are as follows:

1. Suitable for frequent operation, quick and light opening and closing.

2. The fluid resistance is small.

3. Simple structure, relatively small size, light weight and easy maintenance.

4. Good sealing performance

5. It is not restricted by the installation direction, and the flow direction of the medium can be bi-directional.

6. No vibration and low noise.

III. Ball valve VS Plug valve

1. The plug valve has better adjustment ability than the ball valve, but the advantages are limited.

2. Although the plug valve has a larger sealing surface than the ball valve, the sealing effect is good, but it also brings the defects of too much torque and difficult operation.

3. The conventional positive cock structure cannot be made very large due to the influence of the weight of the cock itself. If you want to use a large-size valve, you must use an inverted cock structure. This inevitably reduces the sealing effect under the action of gravity, so we have to use grease Sealing and injected grease cause this valve to be used only for the storage and transportation of natural gas and petroleum, but not for other industries, because the grease will contaminate the medium.

4. The sealing effect of the ball valve is not ideal in theory, but it can be made into a large size. With the improvement of processing accuracy and sealing material, the sealing effect of the ball valve can already meet the actual application requirements very well, and the application range is getting wider and wider.

In short, plug valves are used in occasions with higher sealing requirements, but they are generally smaller in size, and ball valves are more widely used.